Johdanto

Kivihiilen kerrospoltto

Laminatedcoalcombustionistoloosentherawcoalthathasslippedfromthecoalbunkerthrougharotatingroller.Falltothesieveplate.Large-sizedparticlesfallfromthesieveplatetothegrate,andthesmallparticlesizeleakstothegrateunderthesieve.Asthegraterotates,thecoalfeedlevelofthelowerandtheupperisformed,sothatthecoalseamisevenlyventilatedandimproved.Increasethefurnacetemperature,whichisconducivetoburnout.

Kerrostunut polttopolttoaine

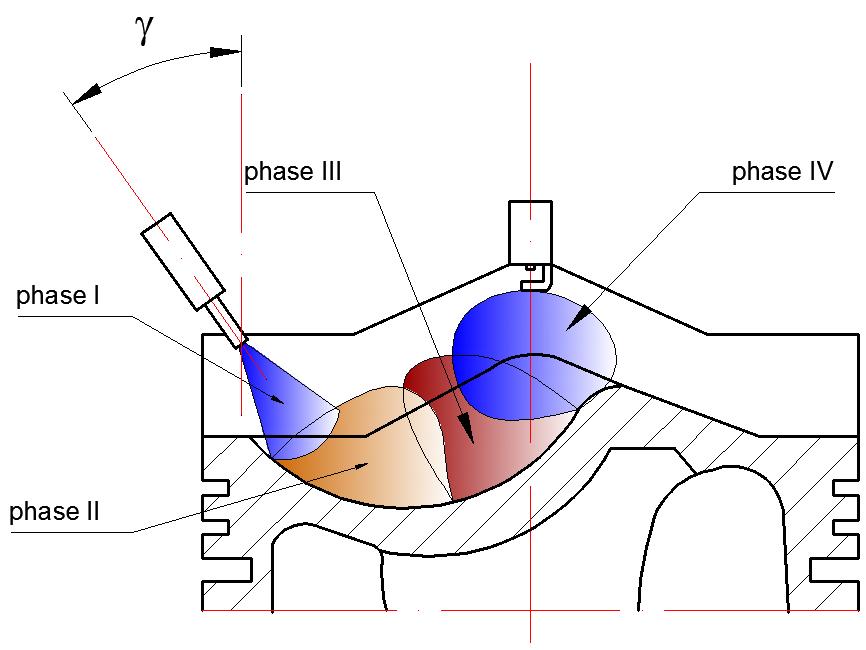

Theso-calledstratifiedcombustionsystemistorelyonintakeswirlormechanicalmethodstostratifytheconcentrationofthemixtureenteringthecylindertomakecombustionThemixtureinthechamberformsarichermixturenearthesparkplugthatiseasytoignite,(air-fuelratiois12to13.5)toensurereliableignition,andmostoftherestofthecombustionchamberisaleanmixture,andinsomeplacesitisevenJustair,inthisway,thetotalair-fuelratiointhecombustionchamberaveragesabove18:1,sometimesevenhigher.Duetotheignitionofthecombustionflameoftherichmixturenearthesparkplug,mostoftheleanmixtureinthecombustionchambercanbeburnednormally,soastoachievethepurposeofusingtheleanmixtureinthegasolineengine.Thiskindofenginethatdividesthemixtureintorichandleanpartsinthecombustionchamberforcombustioniscalledastratifiedcombustionsystem.

Thestratifiedcombustionmodehasarelativelylargethrottleopeningduringtheintakeprocess,whichreducesapartofthethrottleloss.Thekeytotheintakeprocessistoinstallaflapintheintakepipe,whichopensupwards(thenatureoftheprinciple,theactualmodelmaybedifferent)tosealthelowerintakepipe,allowingtheintakeairtoacceleratethrough,andcooperatewiththeomega-shapedpistoncrown.Phaseintotheintakevortex.

Instratifiedcombustion,thefuelinjectiontimeis60°beforetopdeadcenterto45°beforetopdeadcenter.Theinjectiontiminghasagreatinfluenceontheformationofthemixture.Thefuelisinjectedintothepitonthepistoncrown.Theinjectedfuelcombineswiththeswirlintaketoformamixture.Themixtureformationoccursintherangeofcrankshaftangleof40°to50°.Ifitislessthanthisrange,themixturecannotbeignited.Ifitisgreaterthanthisrange,itbecomesahomogeneousstate.Theexcessaircoefficientofstratifiedcombustionisgenerallybetween1.6-3.

Whenigniting,onlythegasinabettermixedstatearoundthesparkplugisignited.Atthistime,thesurroundingfreshairandthegasfromtheexhaustgasrecirculationformagoodheatinsulationprotection,whichreducestheheatdissipationofthecylinderarm.Improvedthermalefficiency.Thecontroloftheignitiontimingisalsoveryimportant,itisonlyinaverynarrowrangeattheendofthecompressionprocess.

Edut ja vaikeudet

Kivihiilen kerrospoltto

1.Palon lämpötehoa voidaan yleensä lisätä noin 8-12 %.

2.Hiilipitoisuutta hiilestä voidaan pienentää noin 10 %:iin.

3.Paranna hiilityyppien sopeutumiskykyä.

4. Muutoksen jälkeen kattilaa voidaan käyttää täydellä kuormalla.

5. Nopea lämmitys ja paineen nousu, helppo sytyttää.

6.Thefailurerateislow,sothattheoriginalburningoftheslagstopperandtheside-sealedcoal-burninghopperarefundamentallyeliminated.

7.Eliminatetheunevencoalfeedingstatethatcausedbygravitywhenthegrateentersthecoalscuttle,wheretherearemanyblocksonbothsidesandalotofpulverizedcoalinthemiddle,soastoachieveuniformcoaldistributionandstratification.

8.Therenovationcostisappropriate,thecostrecoveryisfast,andthecostisbasicallyrecoveredwithinthefirsthalfoftheyear.

Kerrostettu polttopolttoaine

1.Stratifiedcombustionisdefinedas:combustionisdividedintoconcentrationlevels,thefuelconcentrationinthecenterofthecombustionzoneishigher,andtheperipheryofthecombustionzoneismoreair-rich.Many,thefinalresultis"completecombustion".

2.Itisrequiredthatatthemomentofignition,theconcentrationoffuelvaporattheelectrodeofthesparkplugisjustrightforreliableignition.Itdoesn'tmatteriftherearedeviationsinotherareas;butthisisthehardestthingtodoinyears.

3.Whentheengineisat"lowthrottle"oridling,onlyalittlerichgasinthesparkplugareaisrequiredinthecylinder,andtheotherareasarefilledwithfreshair,whichcanachievecompletefuelcombustion.

4.Becausethefinalresultofcombustionisthatthereisexcessoxygen-containingair,thecombustioncanbecompletelythorough,sothefuelefficiencyoftheengineisextremelyhigh,andtherearealmostnobadcombustionpollutantsofconventionalengines.

5.Theatomizationofthefuelfedintothecylinderisnaturallythefinerthebetter,buttheconcentrationrangeislargerthanthefuelconcentrationratiousedinconventionalengines,sotheadjustmentofthe"carburetor"issimplerandbetterDosomething.

6.Becauseexcessairseparatesthecombustionareafromthecylinderwallandpistonduringthe"lowthrottle",theengineisnotheatedveryseriously,andtheengineworkefficiencyisimprovedduetolessheatdissipation.

7.Most"stratifiedcombustion"enginestructuresusenozzlesaimedatsparkplugstoinjectmistfuel,implementhigh-concentrationfuelignitioninanignitionchamber,andthendiffusecombustiontoall.

8.Donotusealargeamountofhomogeneouscombustiongas,andthereisnoneedtoworryaboutlarge-scalecombustiongaspressuredeflagrationaccidents,sotheenginecompressionratiocanbeimproved,whichisverygoodforimprovingtheefficiencyoftheengineinnormaltimes.

9.Thistypeofcombustionmethodiscontrarytoconventionalengines.Theextremefuel-savingstateisparticularlygoodwhenthethrottleissmall,anditadaptstotheactualuseofmostvehiclesusuallyusingsmallthrottlesandoccasionallyusinglargethrottles.

10.Becausethecylinderisnotcompletelyfilledwithhomogeneouscombustionsteam,theengine’s"literpower"isslightlylower,buttheincreaseindisplacementandthedecreaseinheatdissipationsystem,thetotalweightoftheengineshouldbebasicallythesame.

Thepurposeof"stratifiedcombustion"istorationallyapplythearrangementof"moregasandlessoil"tocompletelyburntheoil.Therefore,stratifiedcombustionintheenginemustbebasedonthe"gasmoreoil"arrangement."Less"isthebasiclayout.Themostdifficultandmostcriticalpointisthattheconcentrationofthelocalfuelgasshouldbeadaptedtotheignitionoftheelectricspark.Aslongasthefirecanbeignited,thefuelinotherpartscanbemoreorlessthe"throttlesize".

Ignitionoftherightconcentrationinacylinderwithfierceairflowissimilartopouringacupoffueltoamatchthatisinstantlylittenmetersawayonawindyday.Itisabitdifficult.Inadditiontotheignitionproblem,therearemanyothertechnicalproblems;manydesignstructureshavebeentestedoverseasfordecades,butsofarthereisnoenginewithanidealperfectstandardstructure,andthedifficultycanbeseenfromthis.