Generation method

Generates the most common method of longitudinal magnetic field, and there is a screw coil method.

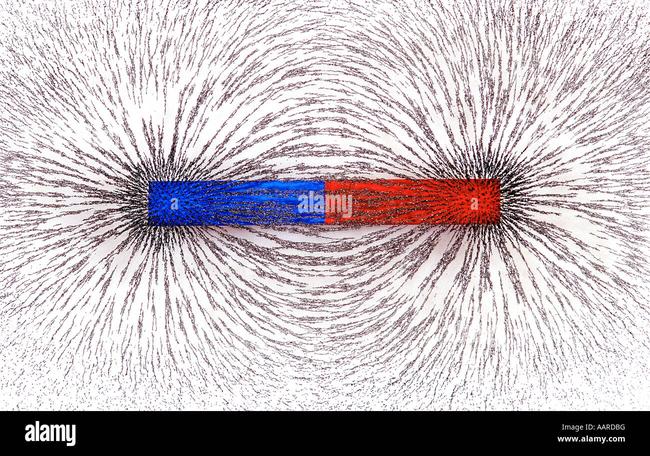

Longitudinal magnetization application The following principle, that is, a magnetic field around the copper wire when the current is passed through the copper wire (Fig. 1). If this copper wire is wound into a coil, there is a magnetic field in the coil. If the copper wire is wound into a wire barrel, the magnetic field of each coil of the wire barrel is combined together to draw a total magnetic field along the longitudinal direction (Fig. 2). In the surface of the copper wire, the magnetic field is the strongest, and therefore, the total longitudinal magnetic field is the strongest in the inner surface of the wire barrel when the cylinder is compared.

put the test piece inside the screw coil with current, and establishes a longitudinal magnetic field in the test piece. The longitudinal magnetic field causes a leak magnet at a crack that is orthogonal to the magnetic line. Cracks that are not less than 45 ° with the magnetic line can also cause leakage magnetic (Figure 3). The screw coil in the actual application is thick and short. The various coils of the screw are squeezed together and is mounted in a sleeve (Fig. 4), at the inner surface of the coil, the magnetic field is stronger, and when the inner surface is left, the magnetic field weaken. When the steel rod is placed in the coil, it is placed close to the inner surface of the coil.

It has been pointed out that the circumferential magnetic field generated by the direct power-on method is unable to see the defects in the inner wall of the hollow test piece, since the magnetic field strength at the inner wall in the test piece is zero. Therefore, the longitudinal magnetic field generated by the screw coils is generally used to see the defects in the walls of the hollow test piece, of course, this defect must be orthogonal to the magnetores or at least 45 ° angles with the magnetic force.

The inner wall and tubes of the tubes shown in the right Fig. 5 will attract iron powder during longitudinal magnetization because they are vertical with the magnetic line. After the steel strip shown in Fig. 6 is longitudinally magnetized, the interlayer contained in which the interlayer is not capable of attracting iron powder. From the right end of the steel strip, the interlayer is like it is perpendicular to the magnetic line, which is because only the side of the interlayer is seen. In fact, this interlayer is extended into the interior of the metal, and its stretching direction is the same as the direction of the magnetic line. Therefore, this interlayer does not have a cross-cut magnetic line, and thus does not attract iron powder.

When magnetizing with a screw coil, the magnetic field produced on both sides of the coil is constant. This effective length relies on the magnetization current used and the magnetic permeability of the magnetized material. The stronger the magnetization current or the larger the magnetic permeability of the material, the greater the effective length. Cracks located within this effective length range can cause sufficient leakage to attract iron powder. The length exceeds the valid length of twice as necessary for twice or more.

The effective magnetizing length of the two sides of the batch coil is approximately 15 to 23 cm, but the effective magnetization length of a batch coil is, and the experience of actual use must be based.

Sometimes the test piece is too large and cannot be placed in the screw coil. In this case, the copper cable can be used around three to six laps on the test piece to carry out longitudinal magnetization. This cable can be connected to two chucks of the magnetic flaw detector. The longitudinal magnetic field generated by the cable also has an effective magnetization distance. Frequent cable magnetizing methods to check the landing gear of the aircraft. The cable can be routed around the fifty circle on the landing gear during the check. It is also possible to be magnetized between the yoke of the electromagnet, which can be excited with direct current or alternating current.

Calculation method

Let us first calculate the magnetic field generated by the ring solenoid. This annular screw tube is uniformly wound on a circle, assumes that the inner diameter of the ring is

When closed back When the radius R of the line is smaller than

The magnetic induction intensity of R at the ring is

can regard the screw coil as part of the radius equal to infinity of the endless ring closure. It is assumed that the length of the screw is

This formula is only approximate because the coil is only distributed over the entire length of the annular solenoid in diameter is infinite. The longer the screw, the smaller the error. When calculating the magnetic field near the biparies in this formula, the error is particularly large.

Calculating the intensity of the magnetic field intensity of the center of the screw coil is:

Any limited length of the magnetic field strength of the batch of bakes is smaller than the magnetic field strength of the unlimited screw coil. For a restricted screw, the magnetic field intensity is the highest at the distance between the two ends of the screw.

Longitudinal magnetism

The opening capability of the vacuum extinguishing chamber can be improved by applying a contact system that produces a longitudinal magnetic field. When the magnetic induction strength of the magnetic field is in the same direction as the arc current, the carrier motion perpendicular to the current direction is greatly reduced, and the quality of electrons is much smaller than ions, especially. The electrons rotate around the magnetic line so that arc shrinkage can occur at larger current. The arc keeps the diffusing mode to ensure less energy reaches the electrode. Here to point out the arc voltage, it is much lower than the arc voltage measured by the transverse magnetic field contacts.