Basic Introduction

1. What is ISO9001 Quality Management System

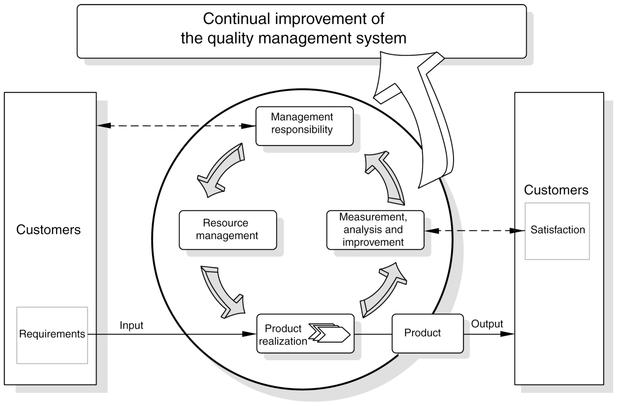

ISO organizations in a wide range of comments, comprehensively consider all walks of life organization requirements Based on the officially promulgated ISO9001 third edition "ISO9001: 2000 Quality Management System Requirements" in 2000, it provides a valid management platform for enterprises. Through the identification of customer needs, the identification of the company's operations, each The definition of job responsibilities, systematically managed, reducing quality risks, and improve customer satisfaction.

II, the founding and development of the ISO9000 system

1, February 23, 1947, ISO (International Standard Organization) organized

2, in 1959, the US Department of Defense put forward quality assurance requirements to military enterprises subordinated by the Ministry of Defense, and stipulated two unified models: military standard MIL-Q-9858A "quality outline requirements "And military standard MIL-I-45208" inspection system requirements ". The contractor should prepare the Quality Assurance Manual according to both models and effectively implement it. The government should gradually inspect and evaluate the implementation of the government. This approach has prompted contractors to conduct comprehensive quality management and have achieved great success.

3, later, this experience of US military enterprises quickly was adopted by other industrial developed national military departments, and gradually promoted to the civilian industry and flourished in Western countries.

4, 1970, BSI develops BS5750, carried out a separate quality assurance system certification business, enabling quality assurance activities to develop from the second party to third-party certification, received all aspects, more Promote the rapid development of quality assurance activities.

5, 1980, ISO organizations established TC176 (Quality Management and Quality Assurance Technology Commission) according to BSI experience and recommendations, specializing in the standards of quality management and quality assurance technology.

6, 1987 TC176 formulated ISO9000 national standard (first edition)

7, 1994 TC176 on the 87 version of the standard stage modification formation 94 version ISO9000 national standard

8, TC176 is amended to ISO9000 national standard for thorough revision in December 15, 2000, ISO9001: 2000 standard

9, China on December 28, 2000, etc. GB / T19001

Enterprise benefits

1, enhance quality management, improve corporate efficiency;

2, enhance customer confidence, and expand market share In the product quality competition, it will always be in an invincible place

3, improve the quality awareness of all-service, improve corporate culture.

4, third party certification, providing the most widely recognition, saving the energy and cost of second party review

5, effectively avoid product responsibility

6. Afterwarding the International Trade "Pass", eliminating international trade barriers

7, legal responsibility is reduced: such as easier licenses, fewer inspections, and simplified reporting requirements.

8, public image and social relationship provide information to consumers' choices.

Application Conditions

Carrying quality certification is to ensure product quality, improve product credibility, protect users and consumers' interests, and promote international trade and development economic and trade cooperation. This certification purpose is very clear, and the company must have a certification to apply for certification.

Chapter 3 of the People's Republic of China Product Quality Certification Management Specialized in terms of conditions and procedures, summarizing, and enterprise application product quality certification must have four basic conditions:

1 Chinese companies hold the "business legal business license" issued by the industrial and commercial administration; foreign enterprises hold registration registration certificates for relevant departments.

2. The product quality is stable and can produce normal mass production. Quality stability refers to the product is qualified for more than one year. Small batch products can not represent the stability of product quality, and must formally become a group of products to produce products can be qualified to apply for certification.

3. The product meets national standards, industry standards and their supplemental technical requirements, or the standards confirmed by the State Council standardized administrative department. The criteria herein refer to national standards or industry standards with international levels. Whether the product meets the standard to be sampled by the National Quality and Technical Supervision Bureau to confirm and approve the sample.

4. The quality system established by the production enterprises complies with the requirements of the quality assurance standards in GB / T19000-ISO9000 families. Estably apply the quality standard system (generally selected ISO9002 to establish a quality system) and effectively operate.

has four conditions above, and companies can apply for certification to the national certification body. Generally speaking, many companies have basically have the top three conditions, and the latter condition is to strive to create. Publicity should be actively carried out to implement the GB / T19000-ISO9000 national standard, combined with the actual reality, and establish a quality system certification must have the following conditions:

1). Chinese enterprise holds the "business legal person" issued by the industry and commerce administrative department Licensed "; foreign companies hold registration registration certificates for relevant departments.

2). Enterprises have established and implemented a silent quality system in accordance with the quality assurance standards in the GB / T19000-ISO9000 family.

The material required for the required material

ISO9001 system certification consulting materials:

ISO9001 system certification consulting requires materials: Quality System Certification (ISO9001): The company's business license, organizational code certificate, license (as required), the materials, standards, etc. required for the product;

required by the

ISO9001 system certification Manage manuals, program files, internal audits, management review materials, and other related forms required for your program file. The third level of job instructions, as well as the record of the operation process.